Inflation is real,

Just can't say no to yum-yums,

Savings have flavor

A few things to note about the author, which may influence how seriously you take this post:

- more tinkerer than roboticist

- is not a great cook

- has limited taste (if at all)

- prefers Papa John's pizza to other pizzas (calorie-to-$ ratio is too high to ignore despite excessive bread-to-flavor ratio)

I've been tracking the use of robotics in food ever since the last few years of my PhD, mostly for fun. In fact, I remember my interviewers (and eventual managers) at JPL asking what I saw myself working in in a decade, and I answered restaurant robotics/automation. Probably not the right answer at that time. (It's a miracle I ever get offered jobs with the way I answer some things) However, I think the problem of preparing/assembling/cooking food is an elegant, complex, but still tractable problem for robotics, because:

- Cooking is semi-structured - There is a bound set of operations that would need to be done to a bound set of ingredients, which are typically packaged/sorted/contained in some repeatable way prior to reaching the chef/cook. The wide range of recipe complexity would (theoretically) allow us to more gradually solve technical challenges while still producing viable demonstrations/products. The job is also confined to a limited space where lighting and locations of tools/ingredients can be controlled.

- Companies have been streamlining/automating cooking via machinery/tools for ages now - It's perhaps more true in processed foods or fast-food restaurants, but many recipes have been reduced to as repeatable and simple of a procedure as possible, to ensure a consistent product to the consumer.

- There are already lots of tools/appliances - We're (hopefully) not cooking with only our bare hands. There are dispensers, serving utensils, mixers, blenders, molds, containers, and various other implements commonly used, and those can also (probably) be modified for use with robotics. I've never been a big fan of trying to get robotics to do anthropomorphic tasks in anthropomorphic (and bio-inspired) ways, when we as engineers can literally build whatever we want.

- Robots/automations are really good at timing - A big part of cooking (imo) is about adding enough heat to some subset of ingredients for some acceptable range of durations. As a person just trying to consume sufficient calories before running off to work in the morning, that can be difficult to track at times. For a robot, not really a challenge, and that seems like a fairly nifty build-in advantage we can leverage.

As I've spent more than a bit of time recently developing/deploying automation, I've grown a little more wary of the future prospects for robotic food startups in the near-term. I've also grown more appreciative of the machinery and techniques developed by the processed food industry over many past decades. Margins for restaurants are razor-thin, upfront costs for automation are high, and manipulation remains difficult. So, how well have the stalwarts in the industry done, where are we at now, and what can we look forward to in the near-term?

Types of Food Robotics Companies

I think it's most worthwhile to categorize food robotics companies by how they prepare the food, which to date hasn't shown too much variety and remains heavily limited by how we're able to physically handle the ingredients:

Beverages (Coffee, Alcohol, and Tea)

Machines for mixing quantities of fluids and dumping them into containers have been around for a long time, so it's not too surprising to see so many examples deployed in the wild, but perhaps their limited commercial success suggests shortcomings with the model or performance (or a blatant oversight on my part). Soda drink dispensers are everywhere, nearly every gas station and college cafeteria has some form of (not-so-great) coffee/cappuccino machine, and you're even likely to see slushie machines at your local robot combat tournament. This is to say that the process of making mixed drinks of many varieties have already been refined and mechanized fairly thoroughly. It would seem that the primary items left to automate would be the order-taking and the physical moving of the customer's container to the various dispensers and then finally to the customer.

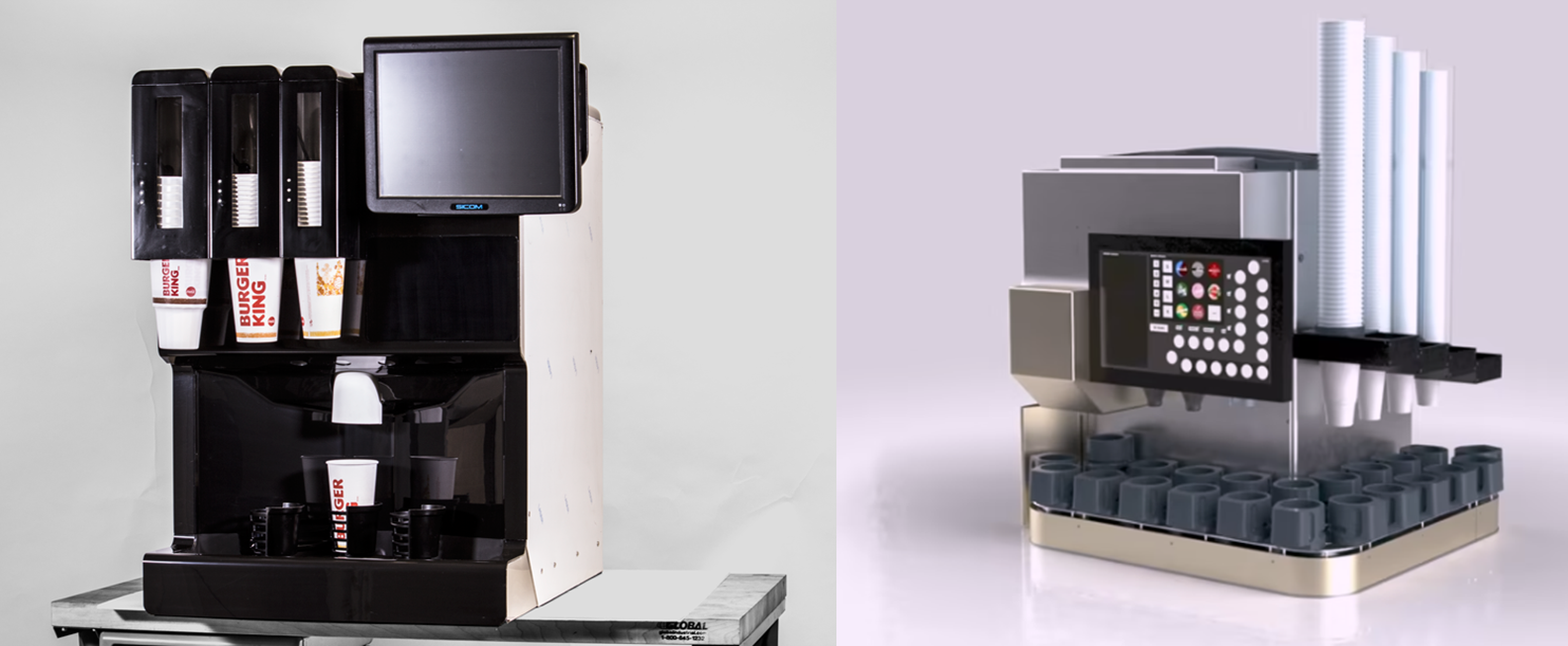

For all the talk of how soda beverages are a high-margin business, it doesn't seem to stand on its own, unless you count vending machines (and maybe we should!). Sodas are typically an add-on to a meal or snack, and perhaps the returns are too meager for automating the placement of a paper cup beneath a valve and pushing a button for some time, especially when the pre-packaged alternative is indistinguishable in taste. Miso Robotics has recently introduced a concept for automatically prepping drinks for customers; and Cornelius, one of the primary vendors for restaurant beverage dispensers, has a similar desktop model as well. Neither approach puts the beverage in the customer's hand. It assists back-of-house and shaves off some time per order, but as with any new tech, also enforces new requirements for upkeep and debugging.

Likewise, you'd think mixed alcoholic drinks would be another highly profitable beverage to automate, and a few companies like Makr Shakr, and Tipsy Robot, have deployed industrial robot arms and a ceiling full of dispensers to make a wide range of mixed cocktails. A quick Google search also returns a long list of DIY robot bartender projects quite easily cobbled together from standard, readily-available 3D-printer parts ([1],[2],[3],[4]). There's no cute umbrella, lemon wedge, or sarcastic bartender discourse, but they're arguably faster and less error-prone than your typical bartender. I've actually visited the Tipsy Robot in Vegas, and I think it's pretty legit and slick: safety laser curtains set up to ensure customer safety, a fun robot performance to deliver my drink, and a high price per drink to remind me that I'm in Vegas. Maybe it's the latter, or maybe location/ambience matter a bit more than automated convenience, but the place was super empty everytime I visited or walked by. I also wonder if alcohol licensing requirements would prevent these sort of establishments from becoming fully automated and personnel-free.

High(er) end coffee perhaps offers the best standalone high-margin opportunity for automation, but I'd argue that the main technological advancement from the majority of robotic coffee kiosks, like CafeX, Crown Coffee, Cofe Plus, and many others, is automating the customer interface, independent of how the product itself is made. I will and should acknowledge that timing and scheduling of orders for hot beverages can be important to how well (and long) they are enjoyed, but it still stands that these kiosk concepts integrate a robotic arm and some flashy tablet displays to deliver a beverage made not all that differently than coffee vending machines from decades ago. How was there a single transition step between instant-coffee vending machines and pairing a robot arm with a Keurig?

To be fair, there are startups, like Rozum Cafe, Ross Digital, and Artly Coffee, using relatively complex robotic arm systems with tool changers and grippers to operate espresso machines in the traditional way. Instead of open-loop motions, there are fiducials or specialized fixtures to make sure the different espresso tooling is properly located and grasped. Instead of a no-contact procedure, various components need to be docked, picked, dropped, etc: a multitude of contact events need to occur reliably in sequence for the espresso to be made. In my opinion, the difference in task complexity is night and day. To me, this begs the question: is that extra complexity (and dramatically higher risk of failure) worth the (supposed) increase in product quality, especially if the majority of the clientele would hardly be able to tell the difference? After all, for all the talk among coffee enthusiasts of getting the perfect brewing profile through an ever more expensive progression of machines, I don't think that level of taste and obsession has reached the main populace. Although there are a multitude of machines built to prepare different forms of coffee with an increasing precision in terms of temperature and timing, I haven't found instances of coffee shops looking to automate the upskilling of their labor. For now, maybe the most economical coffee automation product is a conveyor moving cups beneath a Keurig after all.

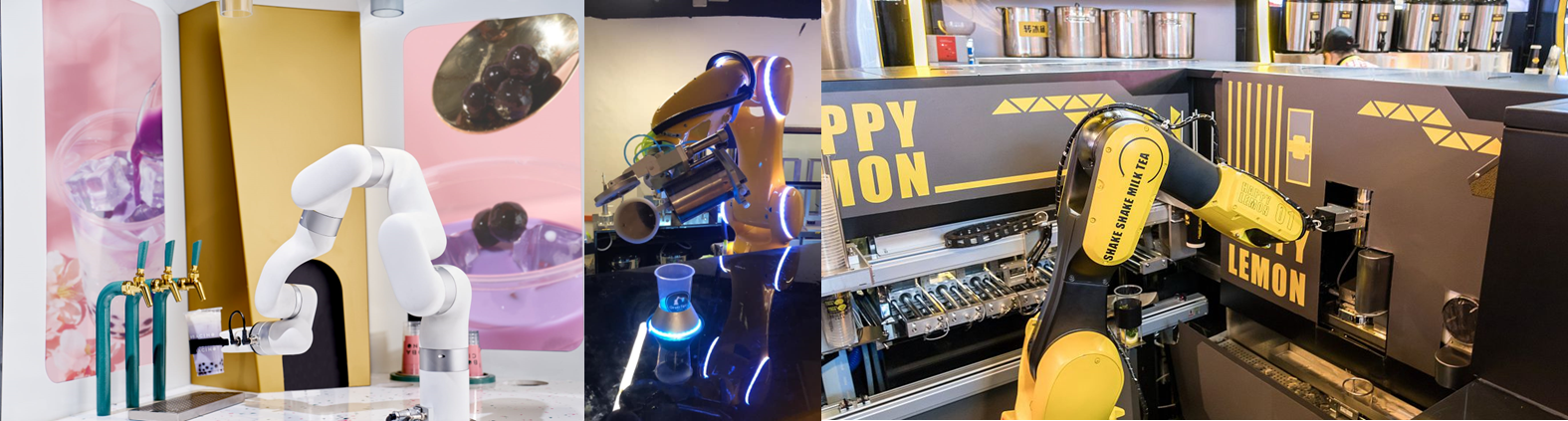

A couple of companies (fewer than I thought), including Bobacino (via Future Pearl Labs), Grab Tea, and Koubei/Happy Lemon (via Taiwan Intelligent Robotics), are also targeting the boba tea application, which already utilizes a bunch of customized table-top appliances as part of a quasi-assembly-line layout not too different from your typical Starbucks. The Grab Tea setup looks very similar to the Makr Shakr solution for cocktails, down to the end-effector (maybe they're made by the same company), and all of the examples above employ some 6-dof arm to handle the cups, though I doubt they really need it. I wonder if it's additional complexity or lack of demand that's prevented this concept from gaining more traction. Ultimately, we're still dumping pre-made ingredients into a cup, but maybe the reliable dispensing of solid ingredients like boba pearls and pudding is still a tad beyond reach for the companies that have tackled this problem so far.

On the other end of the complexity spectrum in the automated beverage space, Blendid makes smoothies pretty much from scratch, using raw ingredients and your typical blender, without any (apparent) shortcuts. It even grips the blender containers with a standard robotic gripper as opposed to a custom end effector or tool-changer and dispenses the finished product via pouring instead of a spout or nozzle. Their magnetic half-moon slider to shift and stage the finished drinks around is also super slick (in my opinion). This concept could've gone with concentrates or pre-packaged pouches (ala Juicero but w/o the subscription nonsense) but I think the concept needs the fresh ingredients to distinguish the end product from a bottled beverage you snag out of a fridge.

Most of these beverage concepts pair some robotic arm with an array of liquid dispensers, boasting of a seemingly impressive range of flavor permutations (though who knows how many of these are worthwhile) and a quantifiable (but insignificant?) improvement in accuracy. I haven't found any published details on these systems' mean time to failure (not surprising), but many of these kiosks are deployed for real, not just set up for well-structured demos; and while regular restocking and cleaning is still necessary, these concepts can certainly run unattended. However, none of these seem particularly fast, and I think the cost of the arms/gantries makes the concept difficult to scale/adjust for the requirements of peak hours. As a result, I'd argue that each kiosk gives you the performance of a slower employee while offering a more limited menu. That's not to say there's no value with those limitations, and automated task scheduling could help mitigate the throughput issue with more optimal timing, but I think that even (arguably) the simplest food product doesn't have an easy path towards full automation to match the performance of your humble local cafe. I also think it's very telling that the large players like Starbucks, Dunkin', or Peet's haven't trialed these automated solutions at all.

Mixed Bowls

A couple of the first robotic concepts that got me interested in food robotics were Sereneti Kitchen (now dead) and Spyce Kitchen (now owned by Sweetgreen): systems that dumped ingredients into a heated container at the proper intervals and then mixed/stirred. I'm a big fan of one-pot recipes and stir-fry, and with regards to robotics, this cooking strategy seems like the next natural progression from beverage dispensing/mixing. The addition of ingredients can be haphazard and messy, and the cooking vessel naturally contains and cages the final product. Most of these concepts rely on some auger or pre-portioned containers of ingredients to dispense the proper amount. Some may discount the "automated-ness" of these concepts since many of the ingredients need to be manually prepped in a particular way, but I think you have to draw the line somewhere.

Chowbotics (acquired and then shuttered by Doordash) seemed(?) to have cornered the salad-making kiosk space in its heyday. A rotary carousel of paddle-wheel-based dispensers would dump a sequence of common salad ingredients and toppings into a bowl. No heating and the use of (mostly) shelf-stable ingredients seemed, in my opinion, to make this a viable and reliable deployment of a fully automated kiosk. The concept and business seemed to go pretty far prior to closing: they had a partnership with Aramark to set up these machines in large businesses (like hospitals and universities), and they went as far as to prepare instructional videos for service technicians. I wonder if the eventual failure was due to the larger customers implementing more WFH and remote work in the wake of the pandemic, or if the output product wasn't all that distinguishable from a pre-packaged and sealed equivalent sold for cheaper from a larger warehouse. The only other automated kiosk I found working on primarily serving cold salads is Bolk, out of France, and even they seemed to recognize the need to provide some hot offerings.

I'd divide the companies working on hot mixed bowls into two camps: those making tabletop appliances that adds ingredients to a heated pot at prescribed intervals and then mixes them, and those working on a more complete end-to-end model to eventually serve as a standalone restaurant. I'd argue that Spyce Kitchen started as a conglomerate of the former and was transitioning to the latter at the time of its acquisition. For me, the key differentiating insight here is that a high-throughput restaurant churning out bowls at scale (e.g. Chipotle, Junzi Kitchen, any ala carte Asian restaurant) isn't likely to cook individual bowls one at a time. They're primarily dumping pre-cooked and warmed ingredients into a bowl with minor topping modifications. There certainly continues to be an opportunity here to customize individual portions to a degree and with a precision unsustainable by manual means, but despite what 'secret menu' acolytes will argue, I think the masses do just fine with a limited menu.

I doubt that Sereneti Kitchen was the first to add an articulating stirrer above a pot, and Spyce probably wasn't the first to deploy a rotating, induction-heated bowl with built-in stirrer, but I think it's pretty insane that the automatic wok/cooker is a tested/proven restaurant appliance available in a range of form factors off of Alibaba, and the mechanization of that cooking motion was first implemented at least a decade ago. There's a semi-automated restaurant called Bowl & Bowl using an off-the-shelf fried-rice-cooker, complete with a mechanism that dumps separate ingredient batches into the pan in the prescribed sequence. Bots and Pots, out of Zagreb, leverages a concept similar to the Sereneti Kitchen prototype in their kitchens for pasta dishes. Likewise, much like how Spyce Kitchen first started, we can now find the rotating, teflon-coated cooking tub w/ internal blade demoed at a multitude of restaurants on Youtube and Wechat, and you can find more advanced models, like the Wokie from Mukunda Foods, that also handle cleaning, cooking guidance, and adding oil.

More "advanced" efforts in the automated food bowl space mix in robotic arms to directly handle the movement of bowls or ingredient containers/dispensers between the storage, heating, and delivery areas. Karakuri has an expandable and modular workcell design with (what I'd call) swappable pods, each of which can be (theoretically) customized to dispense or cook a particular ingredient. It leverages a custom bowl carrier with an outer geometry making it easier for the robotic arm/gripper to hold onto. Aitme flips that script a bit and grabs the individual cooking vessels through a customized post instead. Fixed rollers rotate the inductively-heated bowls to generate the mixing motion. Beastro, via Kitchen Robotics, replaces the robotic arm with a customized gantry and chutes/slides for a more compact kiosk form factor; and they, like Chowbotics, are seemingly far along in their development to have started focusing on usability/deployment. Nommi, Mezli, RoboEatz, and Hyphen are other groups also developing alternative ways to move a bowl beneath various dispenser designs.

A slightly different subset of automated food-bowl companies incorporate freshly-cooked (and sometimes freshly mixed/extruded) noodles/pasta, which for the most part means the addition of perforated strainers dipped into a boiling vat of water and a flipping/dumping motion to transfer the noodles. Cala focuses on Italian pasta dishes while WangJieXie has deployed some standalone noodle soup stands to demonstrate their automatic noodle makers. P-Robo from Techmagic shuttles a cooking vessel back and forth between a noodle dispenser and a sous chef who adds the final garnishes and makes the dish more presentable. I've often thought that hearty soups or thick pasta sauces make for ideal components in autonomously-cooked dishes, as they can be more easily dispensed and kept warm/homogeneously-mixed for longer periods of time while immediately upgrading a dish that would otherwise be indistinguishable from a vacuum sealed box out of a grocery store fridge. That said, maybe I'm severely underestimating the difficulty/cost of keeping food warm and fresh.

Now, this is pure speculation on my part, but as I alluded to earlier: while an all-in-one appliance may make a single dish/serving at a time, a restaurant is more likely to prep larger batches, keep them warm, and then parcel them out depending on customer orders. There's probably also limitations to what a teflon-coated, induction-heated cylinder can properly cook. I don't think Chipotle is transitioning to rotating drums to cook their barbacoa and carne asada, though I guess you could argue that a higher BTU cooking flame and a non-linear rotational trajectory could open possibilities beyond just evenly heating up food. The most recent videos from Mezli and Spyce seem to separate the cooking and dispensing steps, as well as hiding how the hot items are cooked. I would guess that it's more than just the parceling and portioning of ingredients that are still best handled by a careful human hand.

Pizza

Any attempt at an automated pizza dispenser will (and should) be overshadowed by the efforts and success in the industrial automation already developed for making frozen pizzas. Isn't a frozen pizza just a fresh pizza with an extra step? An entire brand's (DiGiorno) strategy relies on their reheated product being indistinguishable from (or better than) a restaurant equivalent. Likewise, pizza chains are already pretty well-oiled machines, with years of optimized procedures and supply chains. Your local pizza slinger is probably not spinning doughy discs into the air and stoking the fire on their wood-fire oven.

In my opinion, the overall strategy for automated pizza-making is fairly well-understood and tested: mix the dough, shape the dough, smear the sauce, sprinkle on the toppings, heat the pizza. The methodology doesn't seem all that much different from putting together a mixed bowl, except now we have to form the bowl before dispensing the toppings. In addition, toppings aren't as easily contained, and the spatial distribution matters significantly more. Another major challenge lies in miniaturizing the frozen-pizza production line and fitting all that in back of house, a shipping container (Hyper Robotics), or even a truck (Stellar Pizza).

It appears that most (if not all) of the players in this space prep the dough beforehand, whether it's a ball of dough that gets pressed/rolled flat by the machine or a round disc already in the cooking pan. I'd guess that it's unreasonable to mix the dough on demand from both a time and waste perspective without the torrid throughput of a major chain. The machines utilize the same sort of dispenser technology used in mixed bowls, but they can't dump the ingredients all at once, and the dispensation is typically coupled with some relative motion of the pizza pie itself to guarantee an even spread. Some implementations just dispense the sauce via a nozzle, while other ([1],[2]) use a physical massager of sorts. To compensate for the stickiness and compliance of the dough during transfer, systems either use a dedicated tray/plate per pizza or a series of mobile conveyors to avoiding dealing with friction. Pazzi (now defunct) used a nifty array of pins to lift up the pizza and still allow for a slotted spatula to easily go underneath the pizza without needing to get a robot to reliably and dynamically slide beneath the pizza crust without snagging.

The advent of specialized home pizza ovens and popularity of places like Blaze and Pieology would suggest to me that there's an appetite for customizability and freshness available without the wait, and a robot is seemingly well-suited to handle the increase in permutations. However, the failure of Zume just a few years ago, despite being backed by Softbank's coffers, and the more recent closure of Pazzi should compel us to ask if automation (at the customer-facing restaurant level) is worthwhile for this food product. If so much of the ingredients need to be prepped a certain way beforehand, and human assistance is still needed during operation (if only to supervise), how much can you really save on labor costs, and how much better could the food actually taste? As with my thoughts regarding Starbucks above, when the biggest player (Domino's) in the space isn't driving the automation efforts, the potential returns may not be as great as we think. (To be fair, Pizza Hut is driving the Hyper Robotics efforts)

An aside: the author grew up on microwaved (not even oven baked) Totino's pizza and enjoyed it very much

Burgers (and other meat in/on bread)

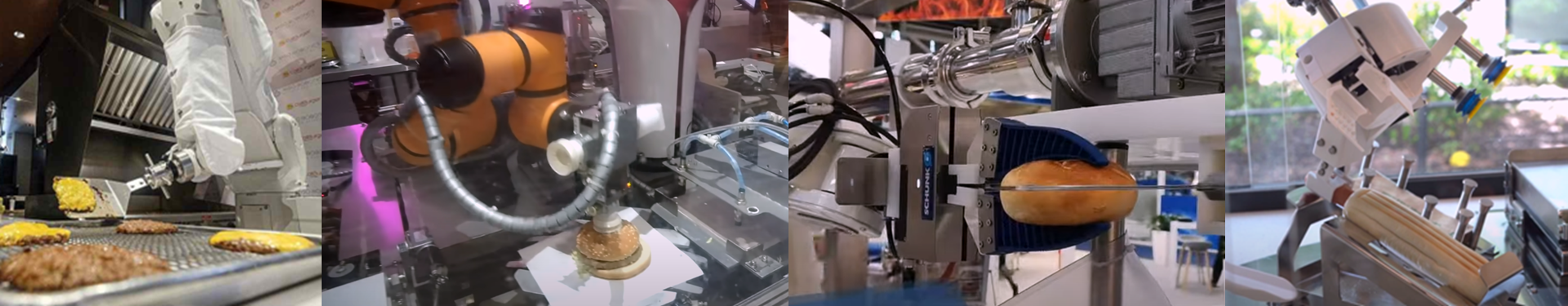

Like I mentioned, Creator (formerly Momentum Machines) first introduced me to food automation, and they spent many years developing their solution before ever revealing it to the public. Their commercial implementation was equal parts performative art piece and whimsical assembly line, handling everything from cutting of the bread and toppings to the cooking of the patties to the final burger assembly (sort of). I've always found it weird that they use a series of flipping paddle wheels to move the burger down the assembly line as opposed to a conveyor, though I guess that allows for multiple burgers to move down the line at different rates if necessary. The final output is really an open-face sandwich, with the burger container structured to help localize the bottom and top buns. That said, despite its temporary (or maybe permanent) closure due to Covid, I believe it's successfully proved out the concept for a modern-day end-to-end autonomous burger shop.

Surprisingly (to me), AMF (yes, the people behind bowling alleys) produced an autonomous burger-making system already back in the 1960s. This suggests that for constrained problems, people have been quite good at developing series of mechanisms to execute even highly complex tasks without the aid of the complex vision/manipulation robotic systems we take for granted today. An amalgation of conveyors, alignment features, and chutes are more than sufficient to put together a burger. Foodom (or Qianxi Robotics Catering Group) developed a similar collection of suction cups, gantries, dispensers, and conveyors to make simple burgers in China, as has RoFood, out of Russia, and RoboBurger scaled back the complexity to focus on a very simple hamburger with only condiment toppings. Like Creator, these efforts share a few limitations: the packaging (whether box or wrapper) is critical in helping keep the burger localized as it gets moved from station to station, the patties along with the other toppings inevitably have to be dropped onto the buns, which pretty much guarantees a mess, and the components handling the meat patties get grimy/greasy pretty fast.

Miso Robotics (more on them later) started off as a burger-flipping robot, cooking and flipping burger patties on a grill with a standard spatula, the old-fashioned way. It's very cool and ambitious, and perhaps it made sense on paper that force/vision feedback in combination with an industrial arm could reliably slip the spatula underneath cooking meat, but I think it says a lot that Miso is no longer pursuing that concept. Some other robotic-arm-based projects appear to primarily be technology demos and include a cold-cut sandwich builder from Vasma Robotics, and a hotdog maker from Velox Alpha, which had an unfortunate failure case captured and uploaded to Reddit.

Deep Frying

The afore-mentioned Miso has apparently found its stride in deep-frying chicken wings and chicken tenders. They provide a robotic arm/gripper on an overhead gantry that picks up baskets of raw meat, dunks them into deep-fryers for the optimal amount of time, and then transfers them to the next stage in the line. The system appears to be easily adaptable to various kitchens with just the addition of fiducials on the baskets and fryer locations. A Korean robotics company has set up a similar concept in Canada (of all places) called Space Robo Chicken (of all things). There's also a chain of fried chicken shops in Korea called Robert Chicken (not a typo) that also handles the dredging and coating of flour. Dedicating an industrial robot arm to deep frying feels excessive, especially since deep fryers with timers and electric lifts already exist. These systems also don't do anything to help with the portioning and packaging of the chicken after frying.

Eggs and Batter (Liquid to Solid)

In my research (aka browsing robotics videos on WeChat and Youtube), I came across two weird edge cases tied (or congealed) together with a key commonality: egg. Eggs start out liquid, easy to dispense haphazardly and evenly, but as they cook, the end product solidifies and (arguably) becomes possible to handle through non-prehensile means. They also bind together ingredients/toppings that otherwise would remain loose. By definition, we're reducing entropy through cooking, but eggs present a convenient situation in food where the application of heat is all you need to do so.

Kurve Automation put together a nifty omelette kiosk in Singapore where customers select their add-ins for a robot arm to add to an omelette. The system swaps out a variety of tools to add egg, mix the omelette in a teflon-coated pan, and then ultimately scoop it out and deliver it to the customer. This solution appears to be purely open-loop, so perhaps it demonstrates more the utility of the humble egg in cooking than any technological advancement.

The Beijing Weilizi Technology company may have tackled an even more difficult challenge in building a kiosk that makes JianBing, a thin Chinese crepe w/ savory fillings. Much like the Kurve Automation omelette-making station, this setup is still open-loop but spreads, lifts, and folds a very thin layer of egg-based batter. It leverages the same rotary cooking base that any food hawker would use to make the same dish.

Reheating and Vending

There are a couple of mixed bowl and pizza vending machine concepts that I removed from their native categories above because it appeared that the kiosks or machines themselves merely heated up pre-packaged meals, and that strategy deserved its own category. In the states, you may occasionally come across a fancier-than-average vending machine that dispenses sandwiches or maybe even fruit. Across the ocean, the options are significantly more extensive, to say the least, and Youtube channels like Ericsurf6 and DancingBacons give a nice sneak peek into that world. In the most basic form, hot-food vending machines aren't too complicated: the internal temperature is just kept high, and maybe the owner needs to refresh/restock a lot more often to deal with perishability. Shelf stability is not necessarily the same as shelf viability. However, the former is a nice thing to leverage if you can apply heat quickly on-demand.

Korea/Japan apparently have self-service ramen stands with shelves of instant ramen, various toppings (including raw eggs!), and hot water dispensers. My interpretation of Yokai Express's videos/patents ([1],[2],[3]) is that they're trying to cram all of that in a box and up the quality at the same time. The fast-casual version of a self-serve, instant ramen stand, if you will. Fast and even heating is not easy, especially if Yokai's patent images are in fact a good representation of what they have and continue to work on. I think we're all familiar with trying to quickly nuke something in the microwave on high and then somehow managing to both burn our mouths and taste cold mush. Maybe (and this is full-on speculation) adding in piping hot broth with agitation is an opportunity to finish off the heating of par-cooked foods.

Another aside: Dave Chang's podcast episode on microwave myths is delightful

I also uncovered several vending machines that seem to just heat up frozen pizza; hence why I didn't include them in the Pizza subsection above. Aldi's Pizzabot, Basil Street, and Pizza Forno all appear to just slide pizza across some heating elements and into a box for the consumer. The videos for the Aldi Pizzabot shows off that process the best, and it's pretty identical to how any fast-food pizza joint would do it: just move the pizza at the right speed through a hot oven zone. Fortunately, pizzas are thin enough to cook thoroughly and quickly even if we only heat convectively from the outside. I've sometimes wondered if the endless racks of frozen pizzas in our grocery store aisles hampers the attraction of automated pizza vending: how much appeal is there for something we can easily re-heat at home and for which we already have a multitude of options? On the other hand, simplifying an automated kiosk or vending machine down to what is essentially a microwave (or science oven) and a conveyor allows for the food to be produced in a much larger and far less constrained facility at scale elsewhere.

"Freeform" Anthropomorphic Cooking

On the other end of simple re-heating and dispensing, there are a few highly ambitious robotic systems built to more closely mimic human chefs and how they "normally" prepare food. Moley and the Samsung Chef Bot may be two of the more well-known "general-purpose", robotic cooking assistants, in theory promising a one-to-one replacement for the kitchen cook through a combination of AI, advanced machine vision, motion capture, and the latest in robotic hardware developments. In practice, both appear to replay a series of complicated-looking, open-loop motions for what ultimately are well-choreographed and well-constrained tasks. Ingredient portioning still appears to happen independently of the robot a priori, and the actual motions in the cooking task do not appear too different from the mechanized mixed bowl concepts described above.

Nala Robotics has deployed what I'd describe as a true industrial, robotic kitchen, designed to compensate for the shortcomings of automation available today while still staying true to conventional cooking methods. They've modified the handles of pots, pans, and other kitchen tools here and there, while adding dispensers where they make sense (why pour out of bottles/pitchers when you don't have to?), but their demo reels show very human-like handling of utensils and cooking vessels. If you were to block out the robotic arms and just focus on the motion of the food, it's a pretty good approximation of what happens in any non-mechanized kitchen. The staging and portioning of the finished food is missing from their published videos, so I'd imagine their primary product is more for a ghost-kitchen setup, serving multiple storefronts/brands with a consolidated back-of-house. It concerns me a tad that their more recent projects ([1],[2]) focus on some of the specializations above rather than expand their general-purpose capabilities. Perhaps the upfront capex differences are substantial and too limiting.

Connected Robotics is another company developing automated kitchens set up explicitly for robotics. Their primary offering leverages a collection of robot arms and customized brackets to prepare and serve ramen, but they've also developed a concept to cook takoyaki balls, complete with a vision system to evaluate when the cooking is complete. Most impressively, many of their prototypes show off modifications to existing kitchen machinery to make them more accessible for a robotic arm to operate through non-prehensile motions, and some of their other demos include retrieving cooked goods from a heated cabinet, serving beer, and cooking burgers.

Other tool-swapping cooking systems include DaVinci Kitchen, Gastronomous, and Dexai. Whereas the first two appear to rely on well-designed mechanical fixtures and hard-coded motions like Nala Robotics, Dexai seems to utilize machine vision and learning to swap out tooling, which can be in a variety of poses/configurations (not specific to a fixed tooling rack), and certainly seems to operate in a more reactive (as opposed to pre-scripted) way (Artly Coffee seems to do the same). From a research perspective, it's a really cool first foray into enabling a system to deal with the unpredictability and messiness of a typical kitchen. From an automation perspective, why increase the complexity when you presumably have full control over the design and structure of the task environment? There's a bigger goal on the farther horizon here for Dexai (and also Connected Robotics), but the Nala, DaVinci, and Gastronomous examples suggest that extensive scripting/planning with just open-loop motions can still get you pretty far.

Intra-Restaurant Logistics

The most mature restaurant robotic tech may not get very far, despite being the most mobile of them all. AMRs/AGVs are arguably having their moment right now, as warehouses continue to get larger, and customers need to shuttle more and more packages back and forth faster than ever. Companies have developed mobile bases for the hospitality, hospital, and security spaces for years now, and companies like Pudu and Bear (among many many others) have some of the more visible demos and installations in restaurants. I wouldn't say basic navigation in indoor spaces is a 100% solved problem, but it's certainly mature, and saving servers the physical labor of carrying loaded and dirty plates back and forth between the kitchen and front of house seems like a tractable task to tackle.

Yet another aside: If you see Pudu's robots in any restaurant, take a quick gander upwards and see if you can find their fiducial markers on the ceiling

I've seen some of these up close, and I've worked on a couple of variants from sketch to prototype; they admirably do exactly what they're designed to do, but nothing more, and that may not be enough for a bustling, cramped restaurant setting. The basic differentially-driven base with a standard suite of proximity sensors mounted onboard is pretty reliable at navigating from point A to B while avoiding (sufficiently large) obstacles in the way. That said, they don't clear the table or load themselves or always know how to handle temporary obstacles in their path...like chairs. When I see these deployments in person, I usually start a timer to see how long it takes before it gets stuck near a crowded table and needs to be rescued by a server. That's not to say these systems are terrible ideas in restaurants, but if a server needs to accompany the bot anyways and now may have extra responsibilities in case of unforeseen edge cases, the net gains start trending negative.

Maybe there's more promise in the sushi conveyor system. Or maybe a sushi lazy river? Or how about an overhead robotic crane?

Where the Tech Continues to Fall Short

Under-structured and Under-constrained Tasks

Many of the examples described so far make compromises and adjustments in how the food is cooked or the ingredients are prepared. A general-purpose, or at least more-easily-adaptable, robotic system would theoretically increase the range of possible cuisines. However, I think efforts like Miso's original foray into burger flipping have shown that even simple, purposeful tasks involving contact with deformable/soft ingredients through tools can be tough to get right. In my opinion, the initial challenge lies in reliable tool swapping and handling (which Dexai appears to be heavily invested in), and the next (pretty much unexplored) challenge relates to how the system utilizes those tools in contact with a food mixture changing in consistency.

Even the simple act of scraping the bottom of the literal (food) barrel lacks a go-to mechanized solution. If the food can't be reliably dumped en masse into a container, a human assistant needs to help. Advances in bin-picking and even the handling of deformable food don't quite start to address the physical requirements in just assembling a plate. Foodly, via the RP Corporation, may be one of the more advanced solutions in this space, and the end-product is rudimentary at best. Not a single robotic installation for automated frying seems to have a method to portion the end-product for the customer.

It shouldn't be surprising then, that ingredient preparation, whether that's just portioning or slicing vegetables/meat to the right size, remains a manual endeavor. Despite there already being food processors (and the Slap-Chop, of all things), even fast-food restaurants may insist on hand-sliced ingredients for quality, texture, and mouth feel reasons. Researchers have certainly attempted the task, but I guess you could say efforts have stayed mostly academic to date. It's still far easier to manipulate a container than what's in the container, so there appears to be significant opportunity in developing new end-effectors for food and more adaptive methods for handling utensils.

Scaling Throughput

I've often been told that robotics is theoretically easy to scale, because you just invest in another one once you reach sufficient savings on the first one, but I disagree. Automation needs both support equipment and space that most establishments probably can't accommodate, while delivering a fraction of the flexibility that a minimal-wage employee with minimal training could provide. Without an overhaul of the line, there's no straightforward way to parallelize any intermediary step. Worse yet, a lot of the examples above show many of the subsystems simply sitting idle if the dish being prepared is at another step.

Despite the supposed programmable flexibility/adaptability of robotics, no setup that I've seen can re-task its manipulator for another sub-task on-demand. Rather than adopt the sense-think-act description of robotics, I rather like thinking of a robot as a mechanism that can execute different tasks with zero setup time. There's an interesting conundrum where a 6-dof arm theoretically gives you more capability, albeit capability that is unlikely to be fully leveraged once the installation is fully-developed and locked in. Even if it were an option for onsite technicians or savvy back-of-house workers, I think the re-setup and re-tasking cost would need to be exceptionally low (if not zero) for it to even be worth considering.

One thing I don't hear being discussed is how these automated systems would handle peak vs off-peak hours. The bulk of the food automation examples deployed so far also arguably operate slower than the greenest human equivalent. If we're to design for the worst case, that could end up being a substantial increase in upfront cost that will just have to sit idle. You can't adjust the schedule and bring in extra workforce when you need it. Aside from some of the beverage examples, I don't think any of the restaurant automation examples I've found operate in your peak, line-out-the-door conditions.

The costs (both upfront and upkeep) of scaling make me wonder if the true unrealized gains in restaurant automation require us to go back further back-of-house and embrace the gains we've already achieved in mechanizing the production of prepackaged and frozen goods. Instead of shrinking and moving that entire system as close to front-of-house as possible in the standalone kiosk model, has anyone (maybe Cloud Kitchens and Kitchen United?) focused on decoupling the par-cooking from the finishing and only moving the latter to the customer? How impressive does the customer-facing science oven really need to be as long as the food is good and cheap?

Exceeding Restaurant Quality

When discussing automation, I typically think first about compromises and tradeoffs. How can I simplify the task to make it as reliable and repeatable as possible, and how much of a loss in quality can I incur? For all the examples of restaurant automation we've discussed so far, I can't name a single one where the customer reviews raved about the taste and flavor being better than what you could get from a human cook. Automation strives to maximize margin, which could mean increased yield and quality, but it doesn't have to.

For me, the story of The Melt perhaps best exemplifies misplaced trust in how technology could elevate the dining experience. The precision and accuracy with which we can follow a recipe doesn't enhance flavor if the recipe isn't all that good to begin with. I don't think anyone has yet stumbled upon the dish where sub-second time-keeping and sub-gram dispensation truly elevates the food to new, otherwise unreachable, heights. Does a recipe so complex or fragile exist such that it can only be properly made when executed end-to-end by machine? Unlikely (but I'd be happy to be proven wrong!). Perhaps the efforts in the food robotics space can only at best achieve the status of the industrial croissant: not close in quality to the handmade original, but accessible in ways the original could never be for those ready to settle for less.

Cleaning

Who or what is cleaning the cooking vessels? It seems that advances in food automation have conveniently ignored the most ubiquitous and least glamorous job: that of the dishwasher. Grease buildup, sticky/charred leftover food, burnt sauces could all add an unfortunate surprise ingredient in the next dish that's prepared. The vast majority of the examples above use disposable plates/bowls to serve the customer, but it would appear that a human assistant still needs to at least spray down the cooking surfaces between orders.

A few of the concepts making mixed bowls ([1],[2],[3],[4]) flip the cooking vessel upside down and spray the insides with some nozzle array, similar to how countertop glass rinsers work. Many of the table-top rotary woks now have this has a built-in feature as well. This seemingly happens without any feedback to ensure that whatever needed to be washed off was actually washed off, and that's yet another reason why a non-stick cooking surface is paramount for the first cooking automation attempts.

Both Connected Robotics and Nala Robotics have shown off some complex cleaning demos that handle various dishware and glassware with suction cups and grippers in a manner similar to how a human dishwasher would. They look slow and deliberate, a far cry from how a frenetic back-of-house may handle the same situation. However, this is yet another semi-structure problem that needs to be solved to move automation and robotics in the food space towards more complex tasks where the system needs to compensate for irregularities from the expected norm. Dishcraft Robotics (defunct as of 2022?) previously worked on this problem for years, eventually resorting custom dishware with embedded magnets to more effectively "solve" the manipulation problem. The size of their system forced them to adopt a dishwashing-as-a-service model as opposed to something that could be deployed onsite at customers' locations. In the large-commercial-kitchen space, we're more likely to see specialized cleaners customized for a particular plate size, or a hybrid approach with people stationed along a conveyor making sure the dirty plates/trays fall within the expected bounds in terms of pose prior to going through a dish carwash of sorts.

How to Turn Up the Heat in Food Robotics?

Literally. Is there a more effective way to transfer heat to the food that the automated system is dispensing? I've recently developed this belief that there are some applications not worth automating if you can't automate them completely. When considering the spatial bounds/limitations of a typical kiosk or restaurant, I think the Japanese/Korean vending machine ecosystem has it right: prepare the food 90% of the way off-site, using whatever traditional automation tools or hybrid workflows are most convenient, and then quickly heat prior to dispensing to the customer. Arguably, airline food also executes this exact strategy with far more limitations than your robotic kiosk.

Heating's seemingly not that sexy of a problem, but whether it's air fryers, sous vide, or the Turbochef Oven that's in more places than you probably know, that's the element predominantly dictating the final taste profile. I don't know if Yokai Express had that insight early on, or if they had other motivations, but I think focus on developing a better reheating method allowed them to simplify their customer-facing kiosk in a smaller footprint, while still (presumably) delivering a yummier product than if they tried to do everything on the spot. Minimizing time from time of order to delivery should be the primary goal, not any lofty aspirations for freshness or machine-driven quality through precision.

As with many (if not most) efforts in deploying robotics, the initial attempts focus on replacing the human element directly while retaining the existing (tried and true) workflows. We should recognize that the natural cadences of machine and man are different, even if we're bold enough to claim that we have full control over the former. If startups insist on automating the existing workflow in-place, I don't know that we've seen evidence of financial viability around the corner, or even the corner after that.