These wheels go around,

Not dry, not wet, let's say moist,

Grime mobility

A year or so ago, I bought a wet mop attachment for a Dyson vacuum while perusing Aliexpress late one night, as one does. In typical "I-didn't-read-properly" fashion, it was incompatible with our Dyson at home, and I was stuck with this random module on my shelf. A little more time (unfortunately) freed up in my schedule in the past few weeks, so I'm back to taking random stuff apart. There's a series of posts I want to do at some point on the number of add-ons and simple electromechanical devices we use in our day-to-day that's basically just a motor-on-a-stick, and how minor variations on that topic and produce so many different uses. I was a little surprised at some of the design choices made in this relatively simple attachment.

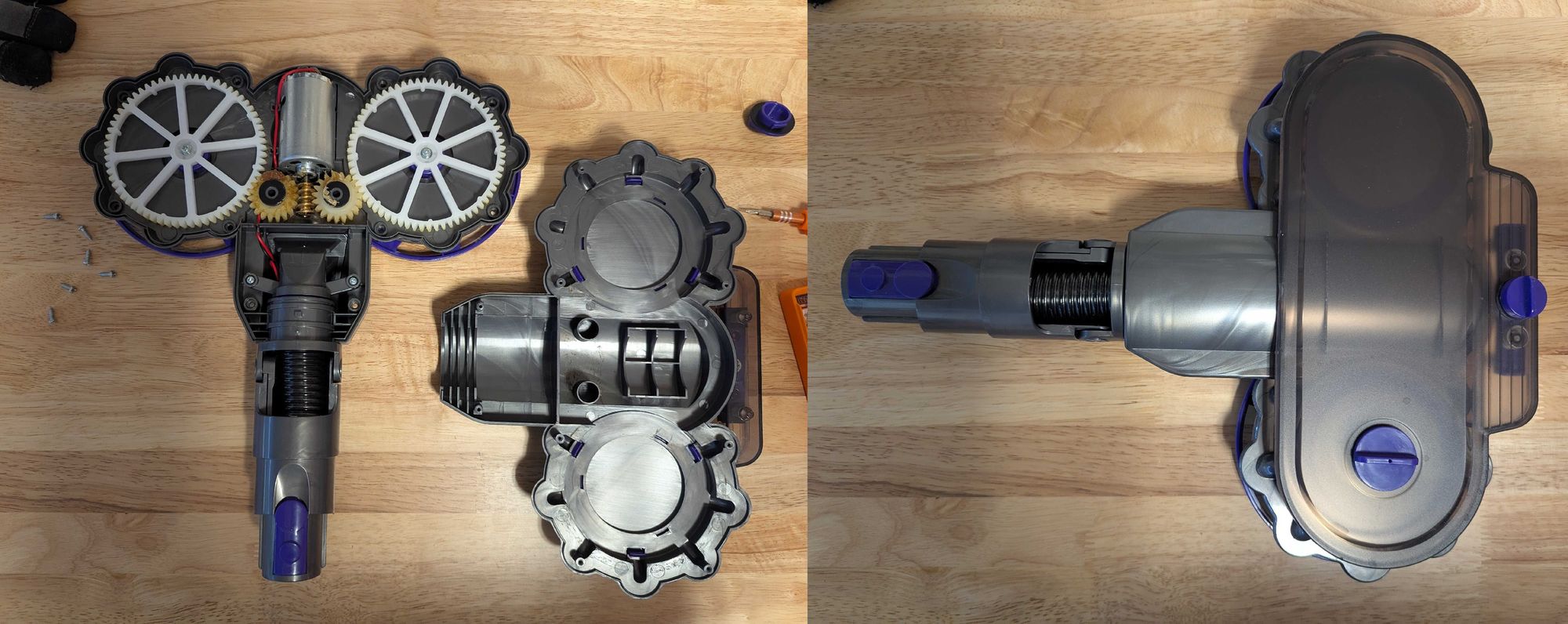

Any Dyson attachment needs to accommodate the vacuum hose and an optional, convenient 12V plug for power. I suppose this interface gets updated between models to move more product and confuse late-night Aliexpress browsers, but it's pretty nifty that we can have a swappable, motorized tool-end. The wet mop attachment is supposed to slowly drip water or cleaning solution in front of the dual rotating pads that funnels grime and dirt into the vacuum inlet port.

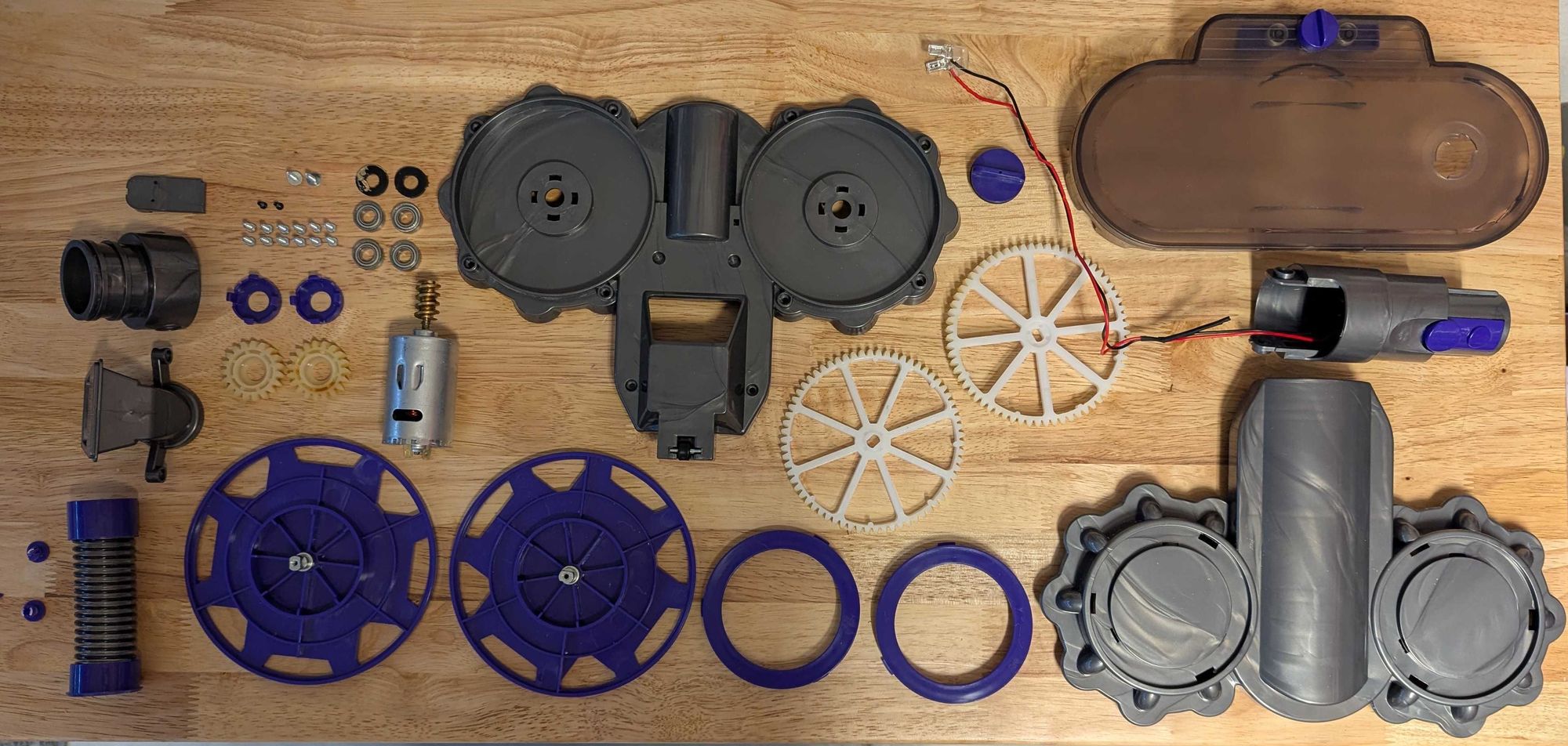

With these sort of mechanisms, I'm generally interested in how they deal with ingress and protecting the electronics and moving bits. For cheaper modules like this, I'm getting the sense that the answer is they really don't. There's not much in the way of seals around the rotational joints or even the main clamshell enclosure. To be fair, this thing's not meant to deal with significant amounts of water or get submerged. The water's only meant to help pick up dust and grime better than a totally dry vac. The grease lubricating the gears should be enough to keep the minor amount of moisture from corroding or damaging anything significantly.

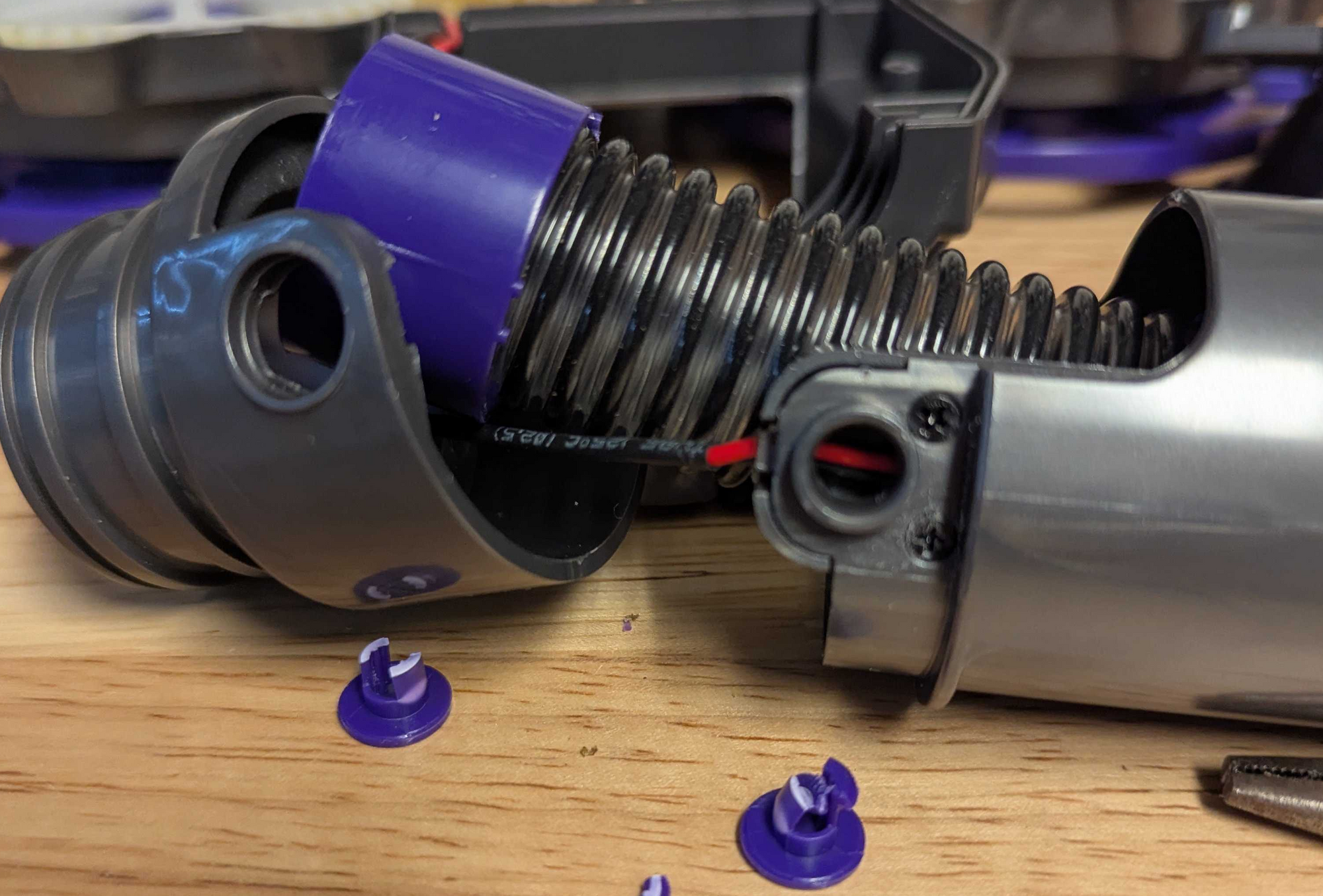

The main pivot or swivel joint around the hose uses snap-fit plugs. The hose prevents any sort of rotary shaft that runs through the middle, and I guess two snap-fit pieces are significantly easier to install than anything w/ fasteners. I'm surprised this joint can hold up to use and abuse without bearings or bushings or at least something stronger than plastic, but maybe I shouldn't be, since the rotary range of motion should be fairly minimal, and you wouldn't expect any crazy side loads. The plugs were not great for disassembly, as the tabs were super-fragile and easily broke off as I tried to depress them w/ pliers while yanking them out.

Our increasing acceptance of accelerated obsolescence in the interest of cheaper products w/ "good-enough" performance has me constantly on the lookout for manufacturing cost-cutting and design compromises. Let's be real: I don't think anyone who buys this module is expecting to be able to take it apart and service it at home if necessary. They'd probably just junk it once it starts to struggle or if a critical component breaks. The water tank is irreversibly welded shut and traps the fastener holding in the air-release valve. The snap-fit plugs at the pivot joint further reinforces a disregard for future disassembly, and yet you see pairs of screws above for brackets or covers that retain the power wiring. I don't get why the wires couldn't be glued down in place, or why the plastic covers couldn't have been welded during assembly.

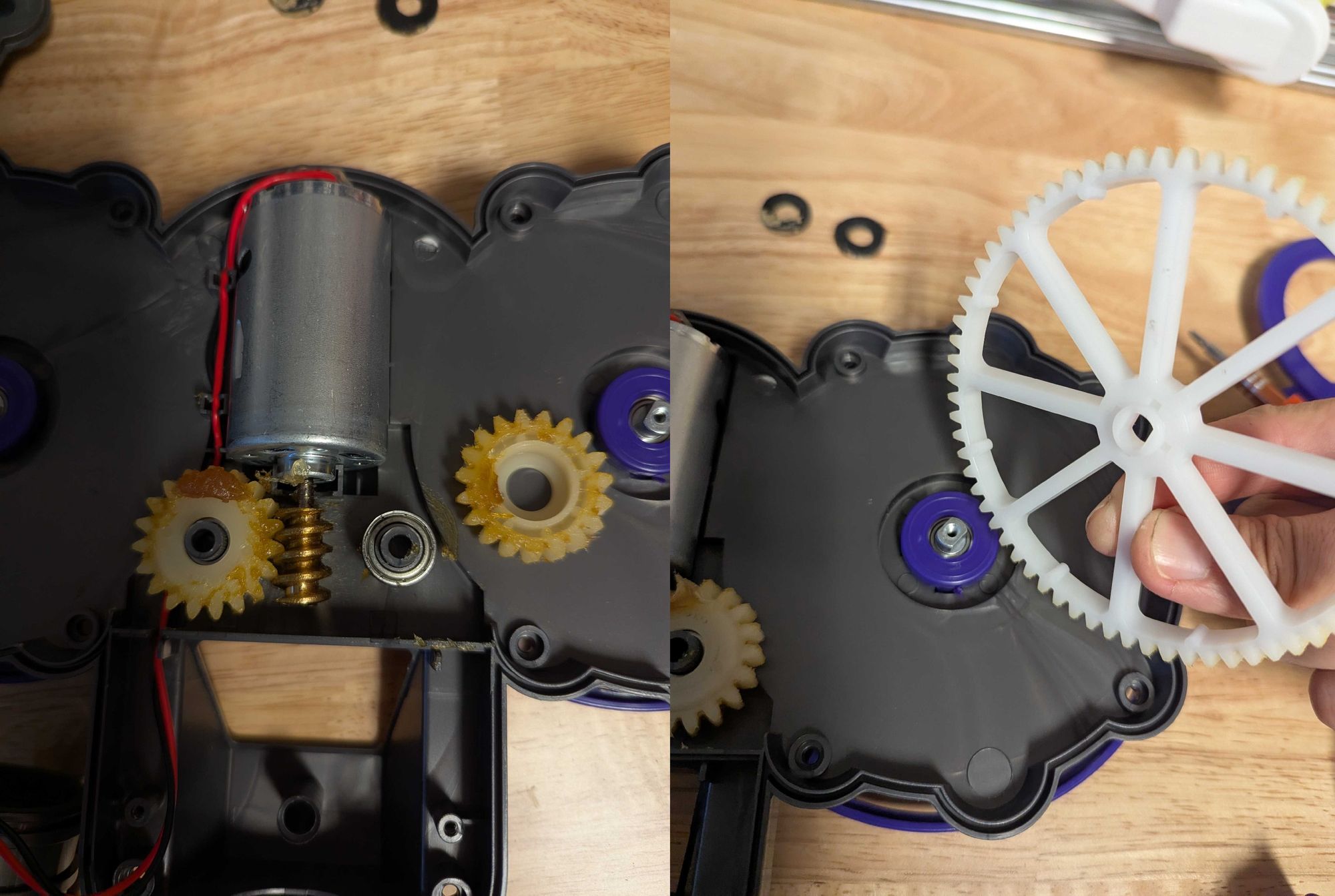

The transmission isn't anything too crazy: single DC motor with worm gear driving a pair of angled spur gears that then drive larger spur gears coupled to the spinning mop cover plates. The mop pads themselves affix to the bottom via velcro. I couldn't see anything clocking or restraining the motor aside from frictional force from the top-half of the clamshell, but with the degree of gear reduction and the non-backdriveability of the thing, I guess the motor isn't ever at risk of getting dislodged due to torque issues from jamming.

I do want to call out the nifty way that the bearings for the large gear and output plates are captured: a single snap-fit enclosure press-fit to the outer race of the bearing anchors to the main body. The assembly of the large gear sandwiches this piece and axially constrains the main output shafts.

The shaft for the mop pad plates seem to be either overmolded or glued to the plastic plate body. I wonder if that's to accommodate the basic 608 bearings used everywhere else. Intuitively, why wouldn't a larger bearing and then a plastic post have sufficed here?

tldr; I think I paid $30 for this thing. Don't do that. The Dyson probably wouldn't work that great as a wet vac anyhow.